Semen Gresik

Semen Gresik

|

Mail US cs@sig.ig

Toll Free 0800 10 88888

|

MANUFACTURING PROCESS

MANUFACTURING PROCESS

CEMENT MANUFACTURING PROCESS FLOW

Cement Manufacturing Process Flow

The success of cement products dearly esteemed by the consumers is the evidence that the cement manufacturing at PT Semen Gresik Rembang has a substantially long process and requires well-planned preparation. The manufacturing process of Semen Gresik can be generally described as follows:

Raw Material Preparation

The two primary raw materials used for cement manufacturing are collected from clay and limestone. All collected raw material is then processed into smaller size using crusher mill and clay cutter before the result is stacked in piles.

Raw Material Grinding

Within the raw material grinding, there are four processes carried out, namely mixing pile, which is a mixture of clay and limestone, limestone pile, silica sand, and copper slag. Each pile generates its own output from each composition which is pre-mixed to be poured in a device called the grinding mill. The output emerging from this mill is in the form of dust material.

Blending Silos

The output from the raw material grinding is then processed in blending silos for homogenization. The purpose is to homogenize, both the size and the quality, to acquire well-blended result.

Pyro Process

Next, after finishing the process in the blending silos, the material is stored in the preheater for the preheating process. After the preheating process, the material is burned in a rotary kiln to approximately 1,400° Celcius. The output from the combustion, in the form of flowing lava, is cooled down in a device called Clinker Cooler. The suddenly cooled down lava produces granular output, commonly known as clinker or slag. The clinker is ground and compressed using the Heavy-Duty Roller Breaker. In this process, the poor quality clinker is channelled to the export bin, while the excellent quality one is stored in the Clinker Storage.

Cement Grinding

After the clinker obtained from the combustion process, the limestone, gypsum, and alternative materials are re-composed to be reground using Finish Mill or Cement Grinding. The output of this process is no longer in the form of dust but cement powder.

Cement Silo

The cement powder does not immediately go to the final stage but is stored again in Cement Silo. The purpose is to homogenize the quality of the cement that is adjusted to the type of cement that you want to sell and at the same time to store the cement before releasing it to the packer.

Cement Packing Bulk Truck

This is the final process of cement manufacturing. If the bulk cement can be directly processed while in the Cement Silo, which is transported by Bulk Truck, the cement bagging must be initially processed in a packer machine and palletizer machine to be distributed.

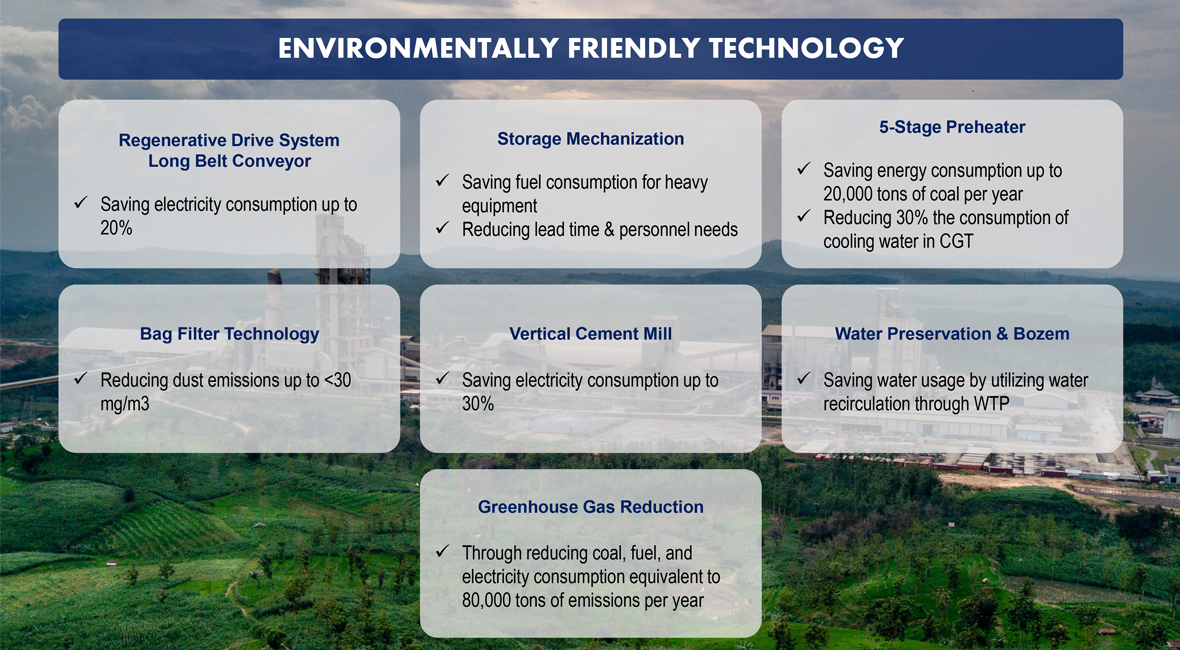

Modern & Environmentally Factory

By using cutting-edge technologies, the manufacturing process at PT Semen Gresik provenly produces highly competitive cement products. To manifest the Company's vision and core competency to provide the best cement products using cutting-edge technologies combined with the efficient and environmentally friendly processes, PT Semen Gresik strives to optimally respond to the challenges of the cement industry with international standard technology and certification support.

Cutting-edge technology

| Technology | Information |

|---|---|

| Crushers | Regenerative Power Long Belt Conveyor |

| Raw Mill | Low Specific Energy Consumption Vertical Mill, Bag Filter technology for Emission Control |

| Kiln | Five Stages Preheater, Cross Bar Clinker Cooler |

| Cement Mill | Low Specific Energy Consumption Vertical Mill |

| Packing Plant | Automatic Palletizing Machine |

| Heavy equipment | Hydraulic |

| Laboratory | Robo Lab by QCX |

| ERP | SAP |

| Process Control System | DCS and PLC |

| Dust Catcher | Main Bag Filter |

The core competency of PT Semen Gresik is to provide the best cement products using cutting-edge technologies combined with an efficient and environmentally friendly process. These featured programs have provenly succeeded in reducing emissions and contributing to environmental conservation around PT Semen Gresik Pabrik Rembang. More than that, one of the environmentally friendly technologies at PT Semen Gresik Pabrik Rembang is the advanced generation of cementing technology in Southeast Asia.